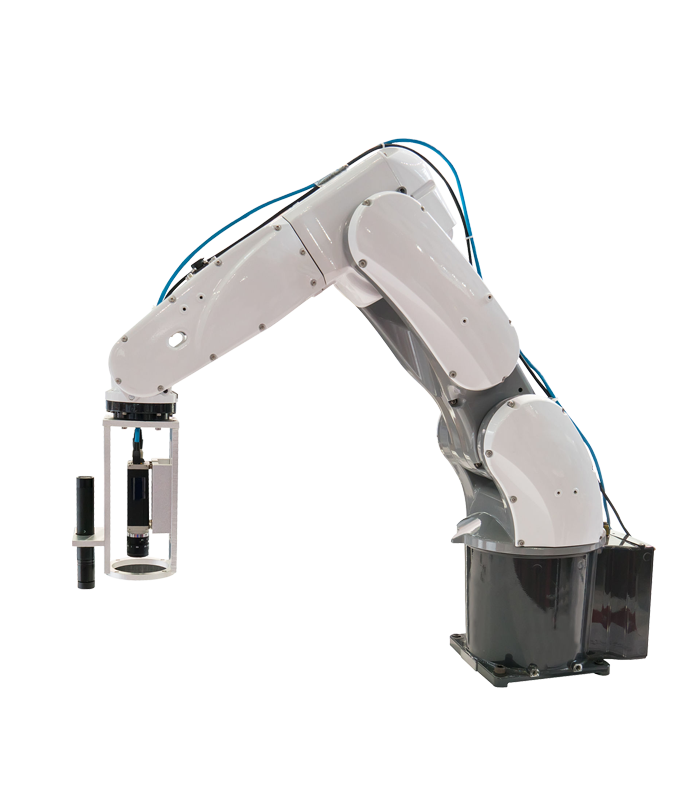

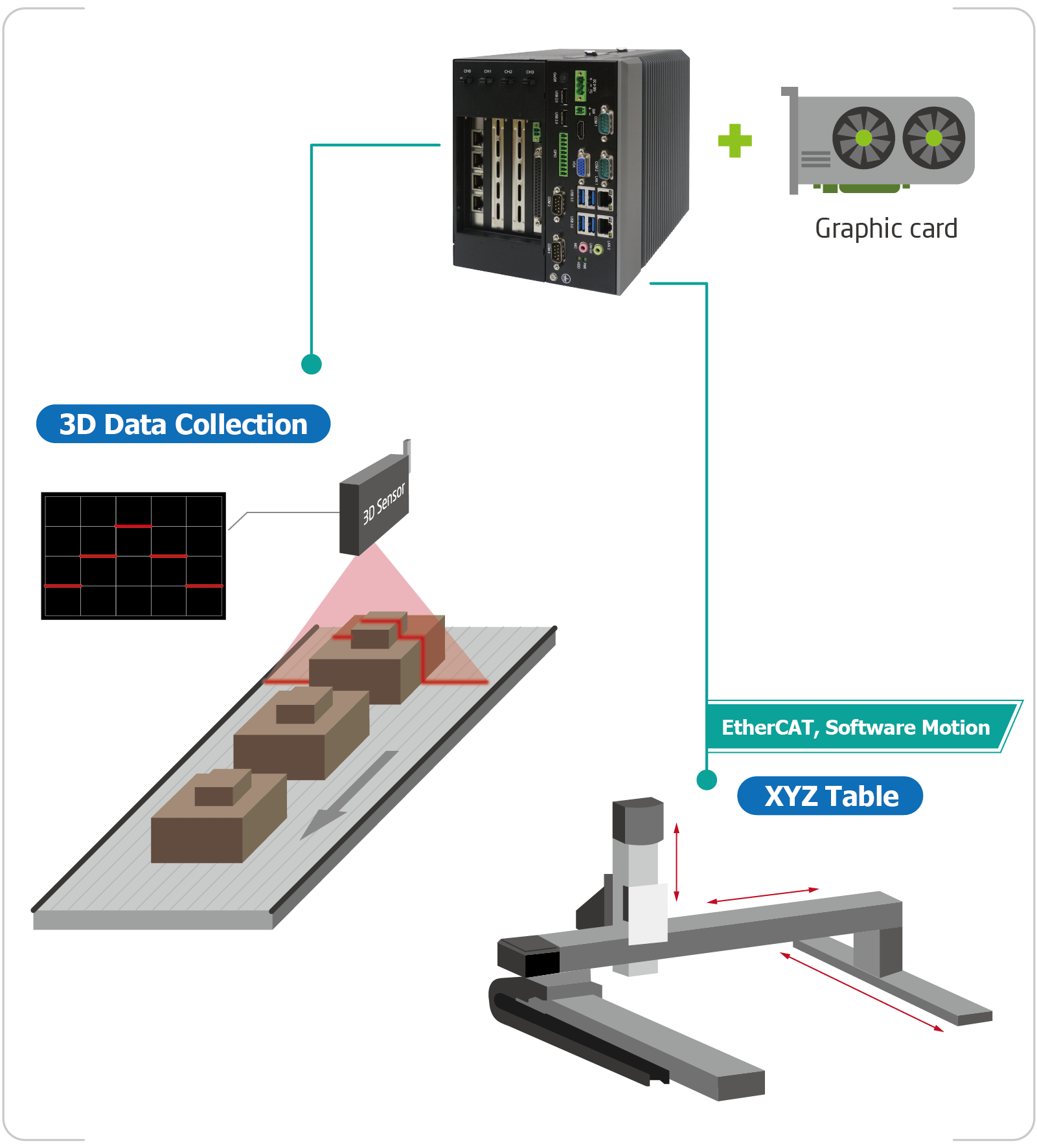

3D Vision application (Positioning & Alignment)

In 3D vision application, huge data of 3D point cloud take a heavy-duty in computing. In order to reduce AVS-504 CPU computing pressure and increase system stability, customers choose APLEX’s AVS-504 high-end platform and 3D camera from Canada’s renowned corporation. After collecting the 3D point cloud data which is calculated by AVS-504, the motion control card will output the data to control automatic equipment for material selection. APLEX’s AVS-504 plays an important role in increasing customers’ production capacity by its outstanding performance. Moreover, it features fanless design to lower maintenance cost and the flexible expansions also benefit the integration of vision application and motion control. With all these advantages, APLEX provides customers the best up-layer control platform and solution.

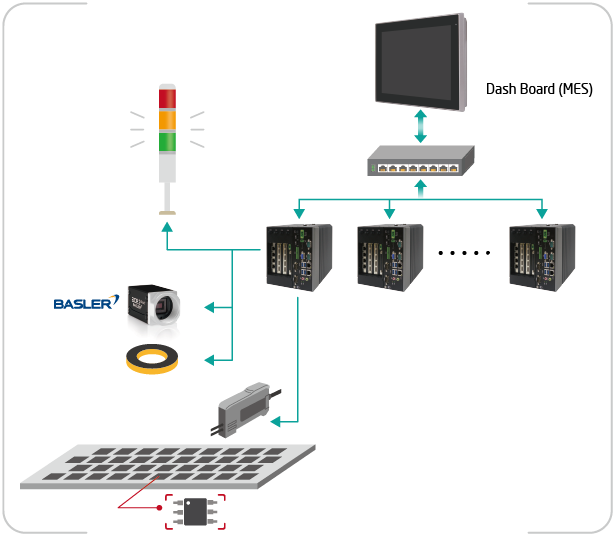

AVS-504 - Compact GigE vision system for AOI application

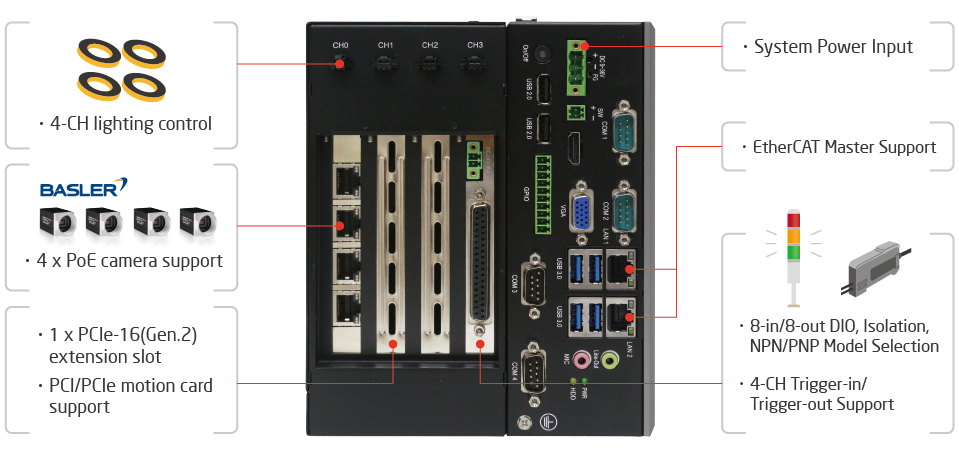

Feature:

- Pre-installed APLEX SDK to support AOI equipment controlled reducing integration efforts.

- Optimized FPGA integration and 7th Core i CPU for us-grade on-fly vision application.

- High product reliability guaranteed by well-validated thermal design, power consumption, and compatibility.

- Flexible software support with adaptive vision, Halcon, Matrox Imaging Library X and many others.

- Ordering information:AVS-504/TB558/TB587/I7-7700T/16G RAM /128G SSD/WIN10 IOT x64

APLEX Solution

APLEX provides complete machine vision solutions, AVS series, from entry to advanced level. AVS-3 series provides good entry level machine vision performance. It is powered by Intel Celeron J1900. It supports lighting control and motion control channels that allow machine to provide basic inspection tasks. Its compact size and fanless design allow space saving. It substantially reduces human error and improves productivity. AVS-5/6 series offers high-end level machine vision performance. AVS-5 series is powered by Intel 7th Gen. Core processors, and AVS-6 series is powered by Intel Xeon processors. Its rugged design provides durability. It supports DIN rail and wall mount to install in various locations. The expansion and add-on cards provide great versatility to take on different industrial applications. AVS-5/6 series is able to provide stability and compatibility for AI/ML based platform to run steadily. It supports PCIe x16 slot for add-on GPU graphic card to allow heavy duty tasks that can meet with most industrial application demands, offering great image processing performance and reliability in industrial applications such as fault detection.

It has up to 4 x PCIe expansion slots to support multiple camera expansion (PoE/GigE/USB3.0) that can take on many kinds of applications.